Home / Hydraulic Services / Hydraulic Repair

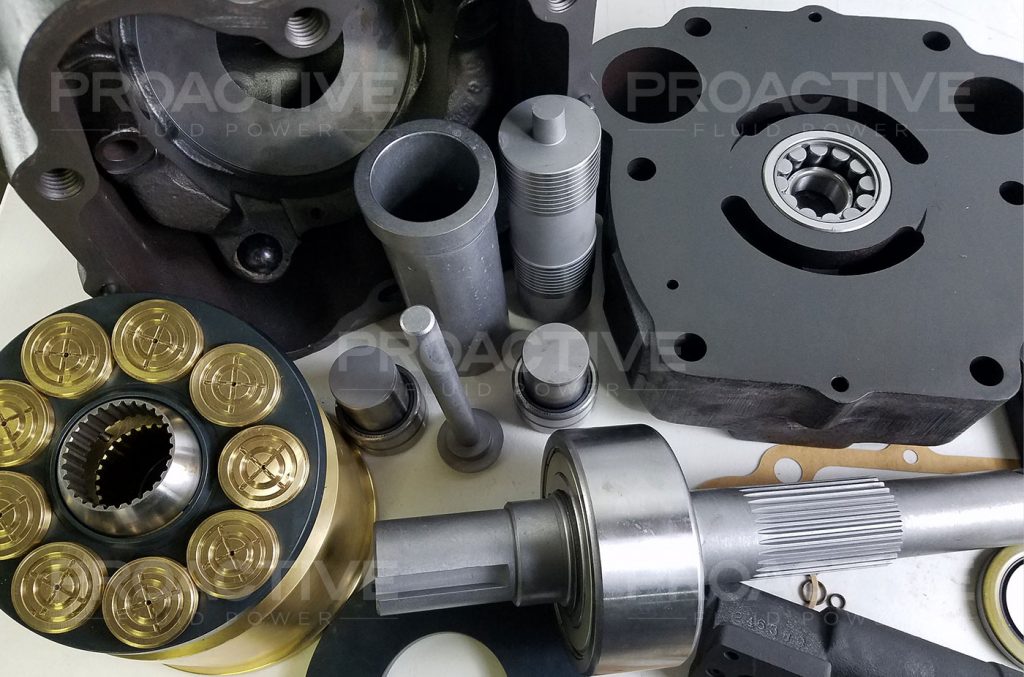

We repair and service the following brands of hydraulics and support current as well as obsolete products dating back to 1940. All repairs are bench tested and include a free failure analysis, startup procedure and matching factory new warranty.

Hydraulic Adjustable Speed Drives

- Manual Lever, Pneumatic, Remote, Electro-Hydraulic Servo and Stem Servo Control

Hydraulic Pumps

- Vane, Piston, Mobile, Industrial, Closed and Open Loop, Fixed and Variable Volume

Hydraulic Motors

- Vane, Piston, Mobile, Industrial, Closed and Open Loop, Fixed and Variable Volume

Hydraulic Valves

- Check, Directional, Flow Control, Pressure Control, Proportional and Servo

- Single and Tandem Stage, Integral Gerotor, Single and Dual Auxiliary Pumps

- Tank, Manifold, Relief and Controlled Flow Types

Hydraulic Repair Service vs. Factory New

Extensive cost savings, minimal downtime, model code identification, failure analysis, component upgrades, custom modifications performed during the hydraulic repair service, OEM matching paint colors, person to person hydraulic technical support and extensive repair and service workmanship warranty are all very important reasons to have your existing hydraulics repaired and serviced. But most importantly, when using our hydraulic repair services, you are maintaining the original hydraulic unit that was engineered and selected specifically for your hydraulic equipment and application.

See the advantages below when considering our hydraulic repair services.

| Hydraulic Repair Services | Factory New | |

| Price | Extensive Savings | Wow! |

| Downtime | Repair Begins Same Day | Up to 1 Year! |

| Tech Support | Included – Same Day | Multiple Weeks |

| Failure Analysis | Included | Not Optional |

| Model Code ID | Included | Not Optional |

| Identification Tag | Multiple Options | Not Optional |

| Paint Color | Multiple Options | Not Optional |

| Repair Upgrades | Multiple Options | Not Optional |

| Custom Mods | Multiple Options | Not Optional |

| Product Settings | Multiple Options | Not Optional |

| Product Testing | Included | Varies per Product |

| Obsolete Products | Multiple Options | System Upgrade |

| Warranty | Extensive Warranty | Varies per Product |

Expensive and Long Lead Times

When ordering factory new, it is typical to experience product design changes, unreasonably long lead times, quantity requirements, advance payments and no return policies. In addition, suggested lead times are frequently extended. Our hydraulic repair services not only provide a substantial cost savings, but also will have your equipment up and running in a fraction of the time.

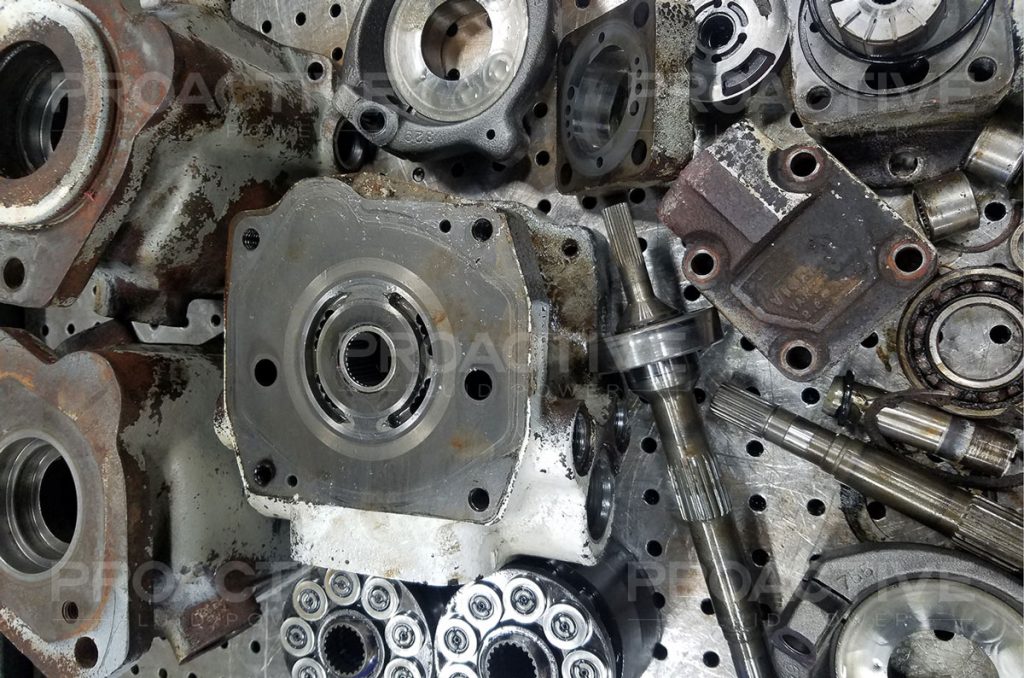

Obsolete without Direct Replacement

Every year the factories release new products and obsolete others. If downtime is acceptable, a new pump, motor, valve or transmission replacement may require a change of oil type, reservoirs, filters, fittings, hoses, electric motors, couplings, mounting brackets and valves. Location and size constraints can also become a huge burden, as well as hourly technician fees required during the design and installation of the newly specified products. Utilizing our hydraulic repair services will allow you to maintain and keep your existing system as it was originally intended and engineered to be.

Why ProActive Fluid Power?

We have over two decades of experience specializing in the same hydraulic brands. This dedication has allowed us to establish an extensive knowledge base of the specific products we support. Since we have repaired the same products thousands of times, we know exactly what to look for and how to repair it correctly the very first time. Companies around the world have used our hydraulic repair services to maintain current as well as obsolete systems dating back to the 1940’s. Our real world experience will keep you up and running well into the future.

Quick Turnaround

Hydraulic repairs are often completed and available for rush delivery within one to two days.

Hydraulic Repair Evaluations

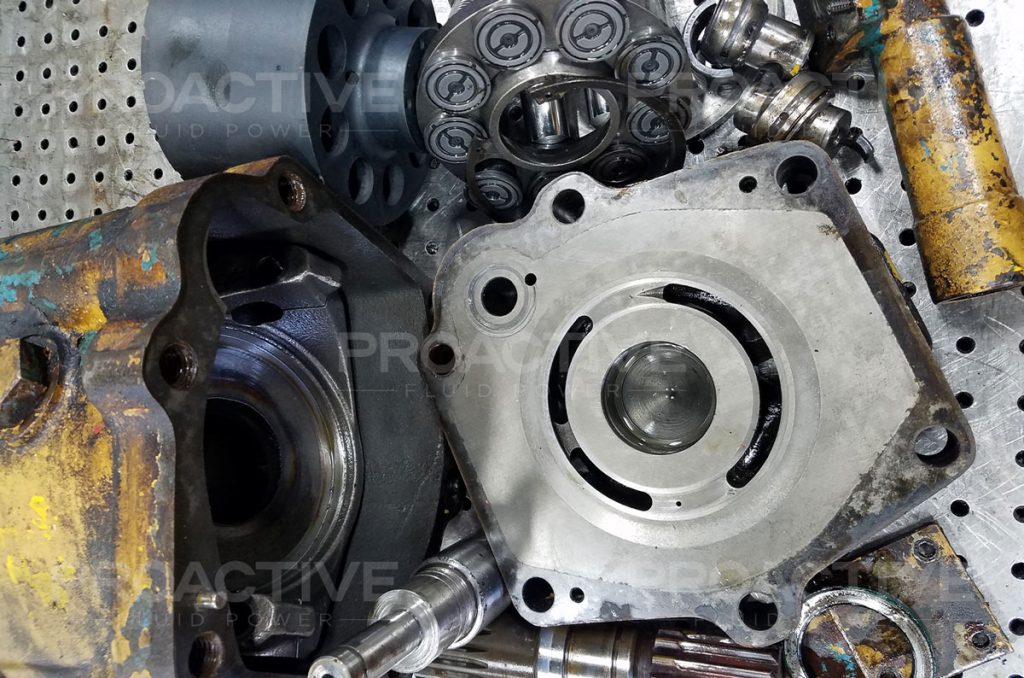

We start by taking pictures and verifying model codes. Individual components are dimensionally compared to factory new tolerances. During this process, the cause of failure is identified and a detailed report is drafted. All hydraulic repairs include these services.

Failure Analysis

A detailed failure analysis is performed when hydraulic assemblies are inspected during our repair services. This information can then be utilized to prevent the newly repaired products from premature failure. When sending your products in for repair or service, please specify any additional information or recent changes in operation. We will consider these details when finalizing our report.

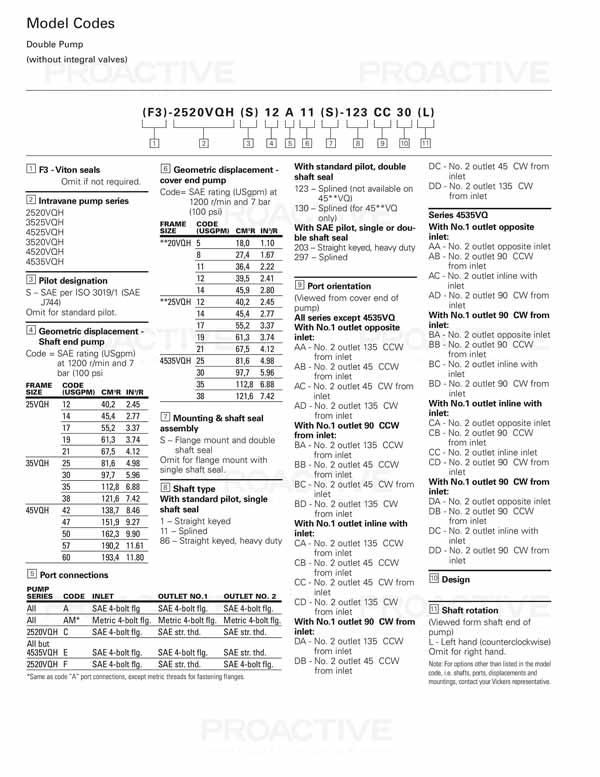

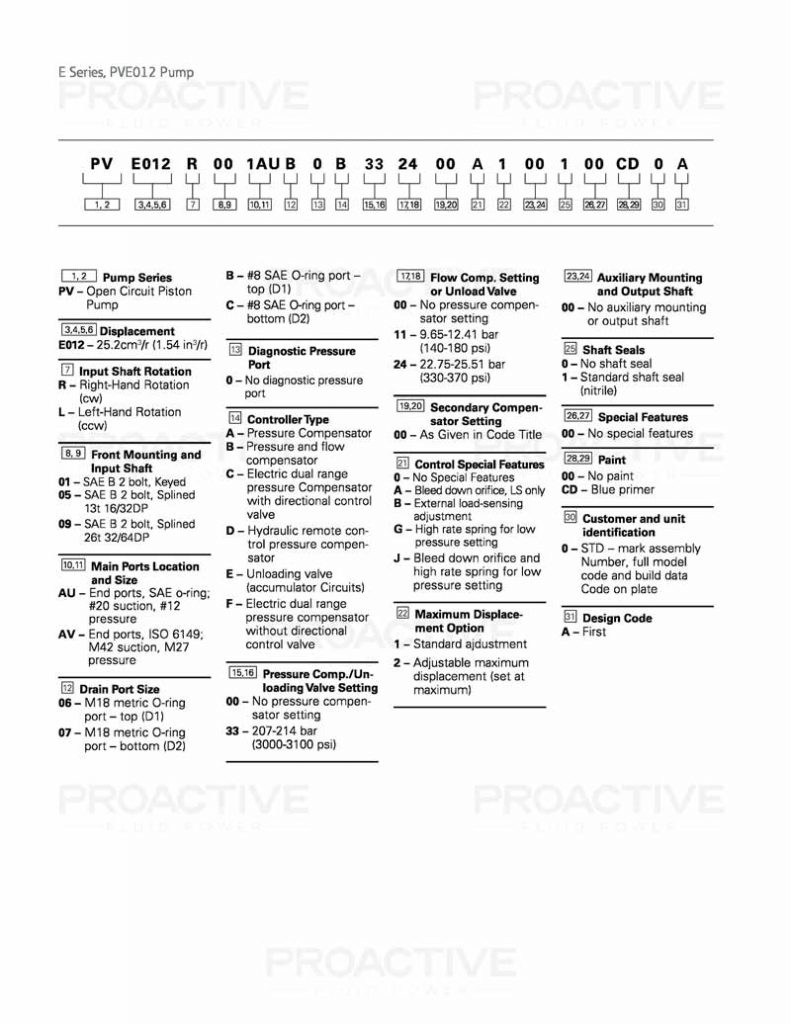

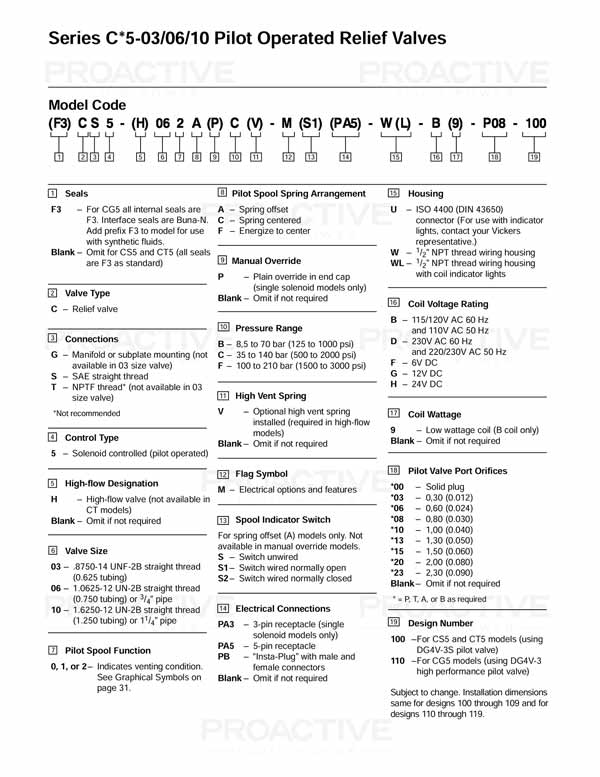

Model Code Identification

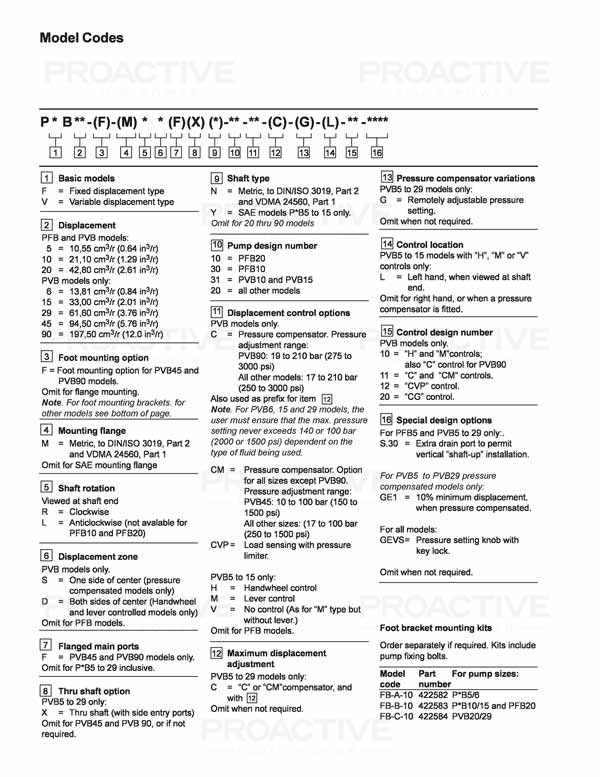

Our technical support department provides a service that can identify and recreate model codes when products were altered or have misplaced labels. When evaluating units sent in for our repair services, we frequently receive products with tags that do not match the actual unit. In most cases, they have been modified in the field but not on the label. This service is completed during the repair evaluation.

Existing Product Settings

Hydraulic repairs are thoroughly tested to existing, customer supplied or factory original settings. We provide this service to guarantee that each repaired assembly meets or exceeds factory original specifications. Utilizing numerous test stations with data acquisition, all repaired and serviced products are guaranteed to perform like new.

Modifications Added During Repair

Displacement, rotation, voltage, spool configurations, high temp or high pressure seals, shaft type, heavy duty or high RPM bearings, port types and port positions are all possibilities.

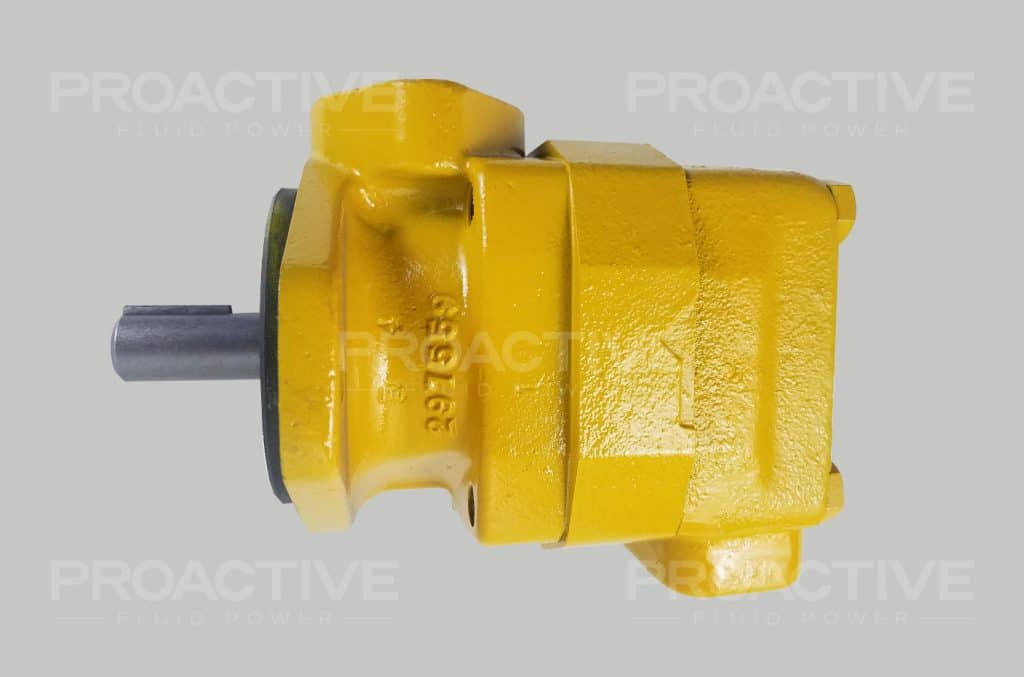

Paint Colors

OEM paint colors are available to match industrial and mobile applications.

Identification Labels

New assembly number and model code identification labels are supplied with all repairs. If requested, custom labels created with your supplied information can be provided. Company name, website address, toll free number, job or internal inventory numbers are commonly requested.

Installation

Please review the solutions section of this website. It provides necessary information to assist with troubleshooting previous failures, oil recommendations, start-up procedures and other additional information required when installing your newly repaired hydraulics back into service.

Part drawings, overhaul manuals, installation and product specification files are available.